Roemheld equipment chosen for workholding on robotised VMC

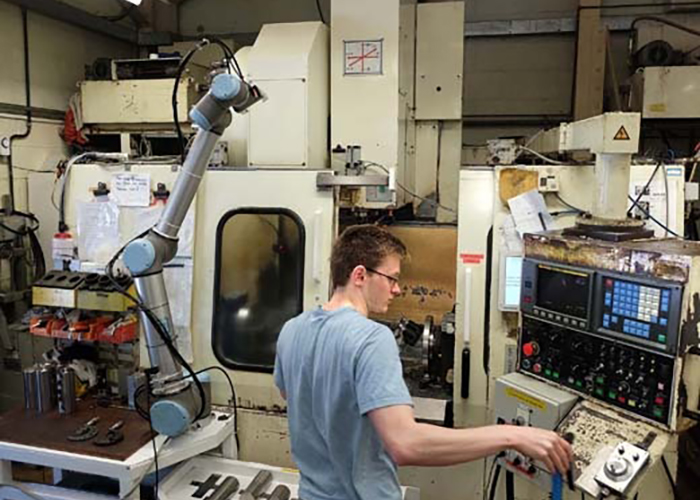

Predominantly a contract machinist of turned parts requiring a significant amount of milling and drilling, Rousant Sherwood Manufacturing (www.rousantsherwood.com) in Henley-on-Thames uses more than a dozen CNC lathes, mainly from Nakamura, Japan. However, for expediency some parts are mill-turned on vertical-spindle machining centres (VMCs), including a line of three Topper machines built in Taiwan, one of which was automated last year to increase production efficiency.

The economic benefit has been dramatic, as the machine now works practically autonomously, so one operator rather than two is able to attend all three Toppers. It has halved the labour cost content of producing a range of stainless steel load cells for a manufacturer of weighing equipment. Different types of load cell are produced in the other two Topper VMCs and there are plans to automate these as well.

As with many automation initiatives in the factory, adaptation of the VMC was the brainchild of Ray Haywood, who owns the subcontracting firm. It is a prime example of how an existing 3-axis machining centre, formerly manually loaded and unloaded in this case for Ops 1 and 2, can be configured for automation at a reasonable cost. Conversion was carried out by Andy Packman at specialist integrator, Projex Design (www.projexdesign.co.uk), which happens to be located on the same industrial estate in Henley.

Workholding equipment supplier Roemheld UK (www.roemheld.co.uk) was chosen to supply a range of hydraulic items to fulfil the project. They include an MC100Z concentric vice and a block cylinder that acts as a tailstock to secure the component between centres for Op 1; a pair of swing clamps to hold the component for Op 2; rotary unions for both pre-existing, pneumatically-operated indexing heads to feed the hydraulics to the fixtures without tangling the hoses; and a hydraulic power pack. Its actuation is sequenced by signals from the controller of the robot, which has been programmed to execute component handling.

As is often the case with Mr Haywood’s equipment purchases, he surfed the Internet to research a hydraulic workholding solution, initially for Op 2, and approached a number of potential suppliers. The response from Roemheld UK was prompt and efficient, added to which the hydraulic swing clamps were deemed to be of high quality, so the order was placed.

The original plan was to use a 2-jaw chuck to hold the component for Op 1, but the Roemheld engineer came up with a better solution based on a hydraulic vice and tailstock, which were also duly purchased.

With the help of Projex Design, the cell was configured so that, in addition to loading, transferring and unloading workpieces, the robot automatically opens and closes both VMC doors, which were suitably modified, making the manufacturing process fully automatic.

The machining sequence

At the start of a day’s production, the robot opens the VMC’s doors, picks up a 67 mm diameter by 180 mm long, cylindrical stainless steel billet weighing 8 kg from a table at the front of the machine, and places it in a horizontal orientation in the hydraulic Roemheld vice, which executes a soft close. The tailstock advances so that its centre pushes the billet to an end stop at the back of the jaw, whereupon full clamping pressure is applied.

With the part now held securely in position and free to be rotated through 360 degrees by the left hand indexing head on which the vice is mounted, Op 1 consists of milling two diametrically opposed flats along the length of the billet, drilling and chamfering three holes through the flats, and drilling and grooving two blind holes on either side such that the web thickness is to within ± 0.05 mm, which is the tightest drawing tolerance. To achieve it, the depth of each blind hole must be controlled to ± 0.025 mm. The component is then indexed through 90 degrees for a small pocket to be milled.

After opening the doors, the robot picks up the part-machined component and transfers it to the Op 2 fixture, mounted on the second indexing head on the right hand side of the VMC table, where the workpiece is secured by the Roemheld swing clamps. A fresh billet is loaded into the vice so that its Op 1 cycle can be completed with Op 2 on the previous part while the doors are closed.

Op 2 comprises drilling and tapping a blind hole in one end face of the billet and drilling two holes at an angle through the small pocket on the side so that they intersect internally. The entire cycle takes just over one hour to complete.

When the robot opens the doors again, the hydraulic pressure is released, the finished part is moved from the Op 2 fixture to the component tray, the part-machined Op 1 workpiece is transferred to the Op 2 position, a new billet is loaded into the Op 1 fixture, the doors are closed and the cycle starts again.

The process continues with minimal operator intervention throughout the day, although it is possible to run the process manually, for instance to prove out an alteration to the machining sequence.

To find out more about Roemheld’s range of workholding and materials handling visit www.roemheld.co.uk or telephone 01462 459052.